Removing a crankshaft pulley bolt can be a real pain, especially if you don’t have an impact gun lying around. But don’t worry, you don’t need to be a mechanic to get this job done! In this article, I’ll show you some easy and effective ways to remove the bolt without using an impact gun. Whether you’re working on your car at home or tackling an engine repair project, these tricks and tips will help you do it like a pro. Let’s dive in!

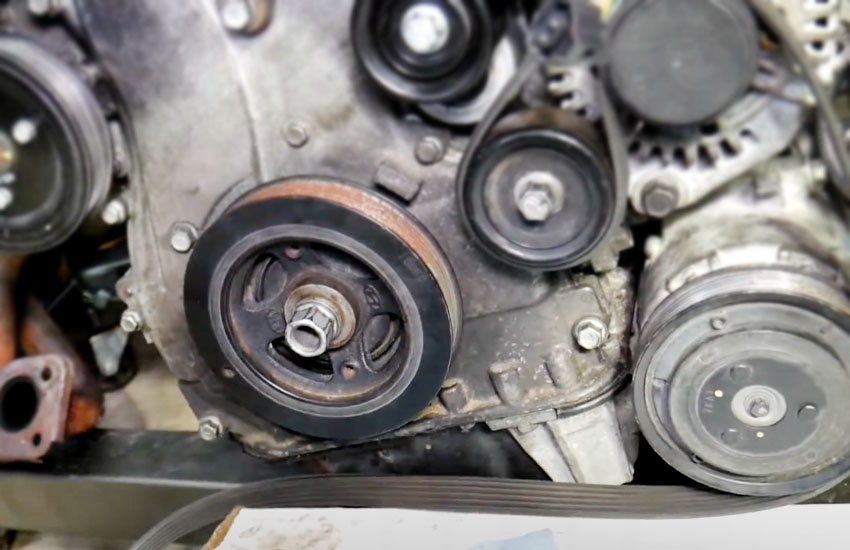

Understanding the Crankshaft Pulley Bolt

Before we get into the nitty-gritty of how to remove the crankshaft pulley bolt, it’s important to understand exactly what you’re dealing with. The crankshaft pulley bolt is a critical component in your engine’s timing system. It helps keep the crankshaft pulley in place, which is responsible for running various components like the alternator, power steering pump, and air conditioning compressor. It’s also tightly secured in your engine, so it’s no surprise that getting it off can be quite the challenge.

Now, the crankshaft pulley bolt isn’t just your average bolt. It’s a big, strong one that’s torqued to high levels—sometimes over 200 lb-ft! And when a bolt is that tight, especially if it’s been on for a while, it can become rusted, corroded, or just plain stubborn. This is what makes it tricky to remove without the right tools, such as an impact gun. The last thing you want is to strip the bolt or break something in the process.

But here’s the good news: while an impact gun is certainly the quickest and easiest way to remove the bolt, it’s not the only option. You can still get the job done without one. In fact, I’ve used a few tricks in the past that worked like a charm, and I’m excited to share them with you.

Why Is the Crankshaft Pulley Bolt So Stubborn?

You might be wondering, “Why is this bolt so tough to remove in the first place?” Well, it all comes down to torque. The crankshaft pulley bolt is often torqued to an extremely high setting because it needs to hold the pulley in place under a lot of stress. If it was too loose, the pulley would wobble or even come off while driving—talk about a major problem.

Another reason the bolt can be stubborn is rust and corrosion. Over time, moisture and heat can cause the metal parts to bond together, making it harder to loosen. So, when you attempt to remove the bolt, you’re not just dealing with the force of the torque; you’re also fighting against these built-up elements. That’s why it’s important to use the right technique and tools to break the bond and safely remove the bolt.

Step-by-Step Guide to Removing the Crankshaft Pulley Bolt

Alright, now we’re getting into the fun stuff! Here’s a step-by-step guide to removing that stubborn crankshaft pulley bolt without using an impact gun. I’ve got a few tricks up my sleeve that I’ve used in the past, so trust me, this is going to be helpful. Let’s take it from the top.

Step 1: Prepare Your Workspace

First thing’s first: make sure you have a clean, organized workspace. This might sound like a no-brainer, but trust me, you’ll appreciate it when you’re working with greasy bolts and tools. Grab a tray or bucket to keep all your parts in one place so they don’t get lost.

You’ll also need a few basic tools to get started, like a socket set, a breaker bar, and a ratchet wrench. A breaker bar, in particular, is essential for applying extra torque when loosening the bolt. You can usually rent one if you don’t own it already.

Lastly, make sure your car is in gear or the parking brake is engaged so that the engine doesn’t move while you’re trying to remove the bolt. I once forgot to do this, and let me tell you, it didn’t end well. You don’t want to be chasing your car down while you’re trying to get the bolt off.

Step 2: Apply Penetrating Oil

One of the easiest ways to make this job easier is to use penetrating oil. Spraying it onto the crankshaft pulley bolt helps break down any rust or corrosion that may have formed over time. It’s a simple but effective step. I usually let it sit for about 15-30 minutes to give it enough time to soak in and loosen the bond between the bolt and the pulley.

You can also use a liquid rust remover if you need something a little stronger. Just be sure to wear gloves, as these chemicals can be a bit harsh on your skin.

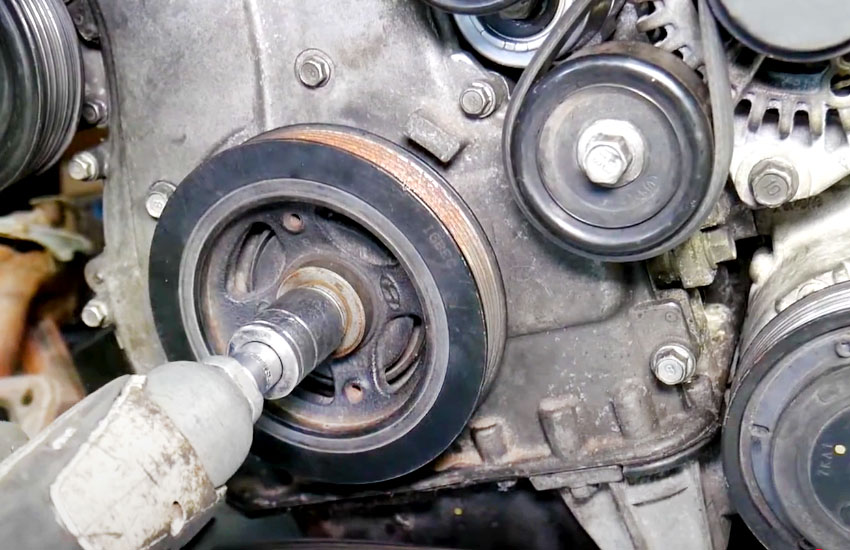

Step 3: Position Your Tools and Set the Breaker Bar

Now it’s time to put some muscle into it. Take your breaker bar and attach the correct socket size for your crankshaft pulley bolt. If you’re not sure which size to use, it’s a good idea to check your vehicle’s manual, as the bolt size can vary. Once the breaker bar is in place, set it up so that you can apply a good amount of force when you pull on it. The longer the breaker bar, the easier it will be to break the bolt loose.

Step 4: Use the Crankshaft Pulley Lock or a Flywheel Tool

If the engine is turning as you try to remove the bolt, you’ll need to use a crankshaft pulley lock or a flywheel tool to keep the engine from rotating. These tools work by locking the crankshaft or flywheel in place, which prevents it from turning while you’re trying to loosen the bolt.

I’ve used a flywheel tool in the past and it works great, especially if you’re working on a manual transmission car. If you don’t have one of these tools, you can sometimes get creative by using a large socket to brace against the engine’s flywheel.

Step 5: Apply Extra Force

Once everything is locked in place, it’s time to apply some serious torque. This is where the breaker bar really comes in handy. Don’t be afraid to put some muscle into it—just make sure you’re pulling straight and steady to avoid stripping the bolt. If you’re still having trouble, you can use a length of pipe as an extension to give the breaker bar more leverage.

Step 6: Heat It Up (If Needed)

If the bolt still won’t budge, you might need to apply heat. You can use a propane torch or a heat gun to heat up the crankshaft pulley bolt for about 5-10 minutes. The heat causes the metal to expand, which may break the rust or corrosion holding the bolt in place. Just be careful not to overheat the area, as excessive heat could damage other components.

Once the bolt has cooled a bit, try loosening it again with your breaker bar. In most cases, the heat will make a big difference.

Step 7: Keep Going Until It Comes Loose

At this point, you should be able to break the bolt free. Don’t rush it; just keep applying force steadily until you hear that satisfying “pop” as the bolt loosens. Once it’s loose enough, you can finish removing it with your hands or a regular wrench.

Congratulations! You’ve successfully removed the crankshaft pulley bolt without using an impact gun.

I hope this guide helped you learn how to remove the crankshaft pulley bolt without the need for an impact gun. With the right tools and a little patience, you can easily tackle this job yourself and save some money on mechanics. If you run into any issues, don’t hesitate to give these methods a try, and remember: it’s all about using the right technique. Good luck!

Frequently Asked Questions

Is it necessary to use penetrating oil?

Yes, applying penetrating oil is a great way to loosen rust or corrosion on the bolt, making it much easier to remove.

Can I remove the crankshaft pulley bolt without a breaker bar?

While it’s possible, a breaker bar gives you more leverage, making it easier to break the bolt free. It’s highly recommended for this task.

Do I need a flywheel lock?

If the engine rotates when you’re trying to loosen the bolt, a flywheel lock will help prevent it from turning and make the process easier.

Is it safe to use heat to loosen the bolt?

Yes, applying controlled heat can help break the bond between the bolt and the pulley, but be cautious not to overheat nearby components.

Can I use a regular wrench instead of a breaker bar?

A regular wrench might not give you enough torque. It’s best to use a breaker bar or something similar for better leverage.

Do I need to replace the crankshaft pulley bolt?

In most cases, you don’t need to replace the bolt unless it’s damaged or stripped. If it’s in good condition, you can reuse it.

Is it okay to use a hammer on the bolt?

It’s generally not recommended to use a hammer directly on the bolt, as it can damage the threads. Instead, focus on applying steady torque.

Can I do this repair without removing the engine?

Yes, in most cases, you don’t need to remove the engine. The crankshaft pulley bolt can be removed with the engine in place.