The purpose of piston rings in an engine is to create a seal between the piston and the cylinder wall, preventing combustion gases from leaking and ensuring efficient compression and combustion. Piston rings play a crucial role in maintaining the engine’s overall performance and reducing oil consumption and emissions.

Without piston rings, the engine would not be able to function effectively, leading to decreased power output and potential damage to the engine components. As the piston moves up and down the cylinder during the combustion process, the piston rings help to maintain proper compression and prevent oil from entering the combustion chamber.

Additionally, they aid in transferring heat away from the piston, enhancing the engine’s durability and reliability.

The Basics Of Piston Rings

Function Of Piston Rings

Piston rings are essential components in an engine, serving crucial functions to ensure optimal performance. The primary role of piston rings is to seal the combustion chamber, preventing the leakage of gases and oil into the crankcase.

Additionally, they regulate the oil consumption by scraping off excess oil from the cylinder walls as the piston moves up and down. Moreover, piston rings aid in the efficient transfer of heat from the piston to the cylinder walls, contributing to proper engine cooling.

Types Of Piston Rings

There are several types of piston rings designed to meet specific engine requirements and operating conditions. The most common types include compression rings, which seal the combustion chamber and prevent gas leakage, and oil control rings, which regulate oil consumption and prevent it from entering the combustion chamber.

Additionally, some engines utilize wiper rings to eliminate excess oil on the cylinder walls, ensuring smooth piston movement and reducing friction. Furthermore, spring-loaded piston rings are used in certain high-performance applications to maintain consistent pressure against the cylinder walls, enhancing sealing capabilities.

Importance Of Piston Rings In Engine Performance

Piston rings play a crucial role in the overall performance of an engine. These small but mighty components are responsible for sealing the combustion chamber and regulating oil consumption. Let’s dive deeper into these important functions:

Sealing The Combustion Chamber

One of the primary purposes of piston rings is to create a tight seal between the piston and the cylinder wall, ensuring optimal compression and preventing any leakage of gases. This seal is critical for maintaining the efficiency of the combustion process inside the engine.

The piston rings exert pressure against the cylinder wall, creating a barrier that prevents the fuel-air mixture from leaking out during the compression stroke and stops exhaust gases from escaping during the power stroke. By maintaining a strong and proper seal, the rings ensure that the full power generated from the combustion is transferred to the crankshaft.

Regulating Oil Consumption

Piston rings also play a vital role in regulating the amount of oil used within the engine. They scrape excess oil from the cylinder walls and return it to the oil pan, preventing it from being burnt during the combustion process.

Proper oil control is essential to maintain the engine’s performance and prevent excessive wear. When the rings scrape off excess oil, they help to minimize oil consumption and maintain the lubrication level required for smooth operation.

If oil consumption exceeds the normal range, it can lead to various issues such as fouled spark plugs, increased emissions, loss of power, and even damage to the catalytic converter. The piston rings act as guardians, ensuring oil consumption remains regulated, and the engine stays healthy.

Signs Of Piston Ring Wear

Piston rings are crucial components of an engine that play a vital role in maintaining proper compression and preventing oil leakage. Over time, piston rings can wear out due to various factors such as high mileage, excessive engine heat, or inadequate lubrication. Understanding the signs of piston ring wear is essential for timely maintenance and preventing further damage to your engine. Two common indicators of piston ring wear are Decreased Engine Power and Increased Oil Consumption.

Decreased Engine Power

One of the primary signs of piston ring wear is a noticeable decline in engine power. When the rings wear out, they are no longer able to create an airtight seal between the piston and the cylinder wall. This results in a loss of compression, causing a decrease in engine power.

You may notice difficulties in accelerating, reduced overall performance, or a lack of responsiveness from your engine. If you experience these symptoms, it is crucial to address the issue promptly to prevent further damage to your engine.

Increased Oil Consumption

Another significant indication of worn piston rings is increased oil consumption. When the rings lose their ability to seal the combustion chamber properly, engine oil can bypass the rings and enter the combustion chamber.

As a result, your engine may burn more oil than usual, leading to a higher oil consumption rate. Keep an eye on your oil levels and look for signs of decreased oil pressure or low oil levels between oil changes. Excessive oil consumption not only affects engine performance but can also lead to other engine problems if left unaddressed.

Maintenance And Replacement Of Piston Rings

Piston rings are small, circular metal rings that are placed around the pistons in an internal combustion engine. Their main purpose is to seal the combustion chamber and prevent the leakage of gases during the combustion process. Additionally, they also help regulate oil consumption, reducing friction, and aiding in heat transfer.

Regular Inspection

Regular inspection of the piston rings is essential to ensure the engine operates optimally. It is recommended to inspect the rings as part of routine maintenance, especially during an engine rebuild or if you notice any signs of engine problems such as excessive oil consumption, loss of power, or blue smoke from the exhaust.

One way to inspect the piston rings is by conducting a compression test, which measures the pressure generated by the combustion process. Low compression levels may indicate worn or damaged rings that need to be replaced.

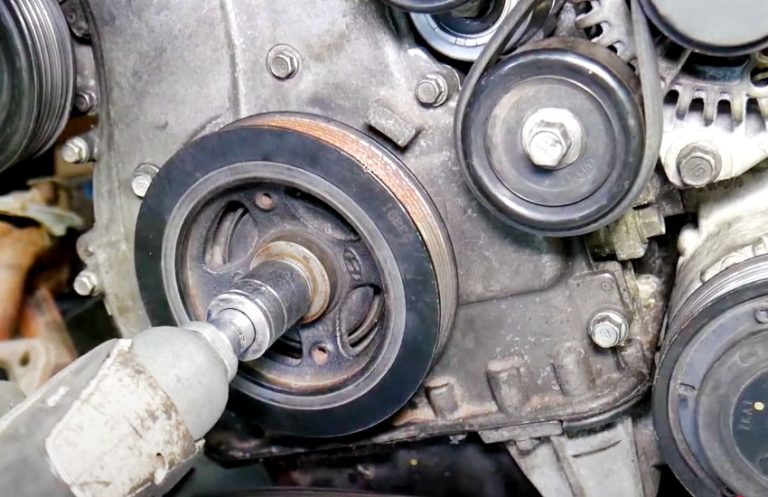

Piston Ring Replacement

If the piston rings are found to be worn, damaged, or not providing a proper seal, replacement is necessary to restore the engine’s performance. It is crucial to follow the manufacturer’s guidelines regarding the replacement procedure, as each engine may have specific requirements.

Generally, the replacement process involves removing the pistons from the engine block, removing the old rings, and installing new rings in their place. It is important to ensure proper ring alignment, gap measurements, and ring tension during the replacement process.

The Bottom Line

Piston rings play a crucial role in ensuring the smooth and efficient performance of an engine. These small but mighty components create a seal between the piston and cylinder wall, preventing the loss of combustion gases and oil leakage. By maintaining proper compression, piston rings contribute to the overall power and fuel efficiency of the engine.

Regular maintenance and replacement of worn-out piston rings are essential for optimal engine performance and longevity.