Drum brakes do have self-adjusting mechanisms. These mechanisms help maintain brake shoe-to-drum clearance.

They automatically compensate for wear on the brake linings, ensuring consistent braking performance and minimizing maintenance needs. Drum brakes are a key component of many vehicles’ braking systems, providing reliable stopping power. As the brake linings wear, it is crucial to maintain the proper clearance between the brake shoes and the drum.

Self-adjusting mechanisms in drum brakes perform this task automatically, ensuring that the brakes continue to function effectively. This feature is essential for maintaining safe and reliable braking performance, reducing the need for frequent adjustments, and enhancing overall vehicle safety. Understandably, understanding the self-adjusting mechanisms in drum brakes is important for vehicle owners and technicians alike.

Credit: www.reddit.com

The Function Of Drum Brakes

Did you know that drum brakes feature self-adjusting mechanisms? These components help maintain optimal braking performance over time by automatically compensating for wear and tear. This results in consistent and reliable braking power for vehicles equipped with drum brake systems.

Drum brakes are an essential part of a vehicle’s braking system and play a crucial role in ensuring safe and reliable stopping power. Understanding the function of drum brakes can help drivers appreciate their significance when it comes to vehicle safety. In this section, we will explore how drum brakes work and the components that make up this vital mechanism.How Drum Brakes Work

Drum brakes operate on a simple yet efficient principle: friction. When you press the brake pedal, hydraulic pressure is created, causing brake shoes to press against the inside of the brake drum. This friction slows down the rotation of the wheel, ultimately bringing the vehicle to a stop. Let’s break down the process step by step:- When the brake pedal is depressed, hydraulic fluid is sent from the master cylinder to the wheel cylinders.

- The wheel cylinders then respond by pushing the brake shoes outward, forcing them against the brake drum.

- The friction between the brake shoes and the drum creates resistance, slowing down the rotation of the wheel.

- As the wheel slows down, so does the vehicle, allowing for controlled stopping power.

Components Of Drum Brakes

To fully understand the function of drum brakes, it’s essential to know about the various components that work together to achieve effective braking. These components include:| Component | Description |

|---|---|

| Brake Drum | A circular metal surface that is attached to the wheel and rotates with it. It serves as a friction surface for the brake shoes. |

| Brake Shoes | Metal plates lined with friction material, also known as brake lining or brake pads. They are the elements that make direct contact with the brake drum to create the necessary friction for braking. |

| Wheel Cylinder | Hydraulic cylinders that contain pistons. When hydraulic pressure is applied, these pistons extend, pushing the brake shoes against the drum. |

| Backing Plate | A sturdy metal plate that holds all the components of the drum brake in place. It serves as a mounting surface and helps distribute forces evenly. |

| Return Springs | Springs that retract the brake shoes from the drum once the brake pedal is released. They ensure the brakes do not rub against the drum when not in use. |

Self-adjusting Mechanisms In Drum Brakes

Drum brakes are a crucial component of a vehicle’s braking system, and understanding the role of self-adjusting mechanisms in drum brakes is essential for maintaining optimal braking performance. Self-adjusting mechanisms in drum brakes ensure the brake shoes remain in proper alignment with the brake drum, allowing for consistent and efficient braking.

Purpose Of Self-adjusting Mechanisms

Self-adjusting mechanisms in drum brakes serve to automatically compensate for wear and tear on the brake shoes, ensuring they remain in the correct position to provide effective braking power. The primary purpose of these mechanisms is to maintain consistent braking performance over time, without the need for manual adjustments.

Mechanism Of Self-adjustment

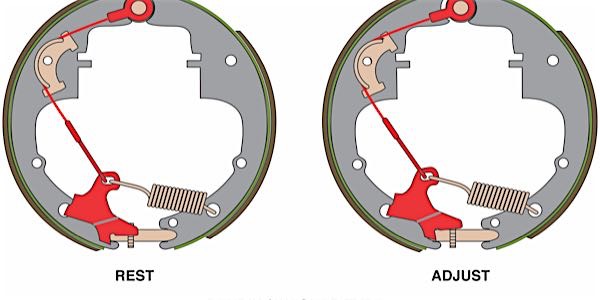

The mechanism of self-adjustment in drum brakes involves a lever or spring mechanism that reacts to the movement of the brake shoes as they wear down. When the brake shoes wear out, the self-adjusting mechanism automatically adjusts the position of the shoes, allowing them to maintain proper contact with the brake drum for optimal braking efficiency.

Advantages Of Self-adjusting Drum Brakes

Self-adjusting drum brakes contribute to better brake performance over time.

Automatic adjustment ensures optimal brake shoe-to-drum clearance for efficient braking.

With consistent contact and reduced wear, braking response remains reliable and responsive.

Self-adjusting mechanisms reduce the risk of brake imbalance and uneven braking.

By maintaining proper alignment, these brakes enhance overall vehicle control and stability.

Regular self-adjustment promotes safer driving conditions by preventing excessive wear.

Importance Of Regular Maintenance

Regular maintenance is crucial for drum brakes to function optimally. While drum brakes are not self-adjusting mechanisms, periodic adjustments are necessary to ensure consistent braking performance and safety on the road. Ensure proper upkeep to prevent potential issues and maintain brake effectiveness.

Preventing Brake Fade

Regular maintenance plays a crucial role in preventing brake fade, which is a common problem in drum brakes. Brake fade occurs when the friction between the brake shoes and drums decreases, resulting in a loss of braking power. This can be extremely dangerous, especially in emergency situations, as the vehicle’s stopping distance increases significantly. By regularly maintaining your drum brakes, you can ensure that they are in optimal condition and minimize the risk of brake fade.

Ensuring Longevity Of Brake System

Another important reason for regular maintenance of drum brakes is to ensure the longevity of the brake system. Drum brakes are exposed to various factors that can contribute to wear and tear, such as debris, moisture, and heat. Over time, these factors can cause the brake shoes to wear down, resulting in reduced braking efficiency. By regularly inspecting and servicing your drum brakes, you can identify any potential issues early on and take the necessary measures to prevent further damage. This not only extends the lifespan of your brake system but also ensures the safety of you and your passengers.

Preventive Maintenance Checklist

To help you maintain your drum brakes effectively, here is a simple preventive maintenance checklist:

- Inspect the drum brakes regularly for any signs of wear or damage.

- Clean the drum brakes and remove any debris or rust buildup.

- Check the brake fluid level and top it up if necessary.

- Adjust the brake shoes to ensure they are properly aligned with the drums.

- Replace worn-out brake shoes or any other damaged components.

- Test the brake system to ensure proper functionality.

By following this checklist and performing regular maintenance, you can keep your drum brakes in optimal condition and reduce the risk of brake failure.

Conclusion

Regular maintenance of drum brakes is essential to prevent brake fade and ensure the longevity of the brake system. By inspecting, cleaning, and adjusting your drum brakes regularly, you can maximize their performance and keep yourself and others safe on the road.

Comparison With Disc Brakes

When it comes to brake systems, self-adjustment mechanisms play a crucial role in maintaining optimum performance and safety on the road. One common question that arises is whether drum brakes have self-adjusting mechanisms, and how they compare to disc brakes in this aspect. Let’s dive into the differences in self-adjustment and performance variation between drum and disc brakes.

Differences In Self-adjustment

Drum brakes are equipped with a self-adjusting mechanism, which continuously compensates for the wear of brake linings. This ensures consistent braking performance and eliminates the need for manual adjustment. On the other hand, disc brakes do not typically have a self-adjusting mechanism and may require periodic manual adjustment as the brake pads wear down.

Performance Variation

When it comes to performance variation, drum brakes with self-adjusting mechanisms tend to maintain more consistent braking performance over time. This is due to the automatic compensation for wear, which minimizes the risk of performance degradation. In contrast, with disc brakes, the performance may vary as the brake pads wear down, necessitating more frequent maintenance and attention to ensure consistent performance.

Failure And Troubleshooting

Drum brakes are equipped with self-adjusting mechanisms, but sometimes these mechanisms can fail to work properly, leading to decreased braking efficiency. Understanding the signs of self-adjustment failure and knowing the corrective measures can help in ensuring the smooth operation of drum brakes.

Signs Of Self-adjustment Failure

1. Uneven braking: Brakes may feel different from left to right and may cause the vehicle to pull to one side during braking. 2. Increased brake pedal travel: The brake pedal may require more force to engage the brakes fully. 3. Excessive brake noise: Grinding, squealing, or unusual noises during braking can indicate a potential self-adjustment failure.

Corrective Measures

When signs of self-adjustment failure are noticed, it’s essential to take corrective actions to ensure proper functioning of the drum brakes. Here are some recommended steps:

- Inspect and adjust the self-adjusting mechanism regularly to ensure it is functioning correctly and is not obstructed by debris or rust.

- Replace worn or damaged components, including brake shoes, springs, and adjuster mechanisms, to restore proper brake function.

- Clean and lubricate the self-adjusting mechanism to prevent binding or sticking, which can hinder its operation.

- Seek professional help if any issues persist, as they may require advanced diagnosis and repair by a qualified technician.

Future Developments In Drum Brake Technology

One exciting future development in drum brake technology is the incorporation of advanced self-adjustment mechanisms. These mechanisms are designed to automatically adjust the brake shoes as they wear down, ensuring optimal performance and reducing the need for manual adjustments. With this advancement, drivers can have peace of mind knowing that their brakes are always operating at their best.

Another significant development on the horizon for drum brakes is their integration with electronic control systems. Through the use of sensors and advanced algorithms, these systems will monitor the brake performance in real-time and make automatic adjustments as necessary. By incorporating electronic control into drum brake technology, manufacturers can enhance safety and responsiveness. This integration will bring drum brakes closer to the performance levels of their disc brake counterparts.

Credit: www.brakeandfrontend.com

Credit: www.brakeandfrontend.com

Conclusion

Drum brakes are not self-adjusting mechanisms. While they are reliable and have been used for many years, they require manual adjustment to ensure proper braking performance. Regular maintenance and inspection are essential to keep drum brakes in optimal working condition.

By understanding the basics of drum brake operation and implementing the necessary adjustments, you can ensure the safety and effectiveness of your vehicle’s braking system.