The crankshaft sensor plays a crucial role in monitoring the engine’s rotational speed and position, providing essential information to the engine control unit (ECU). However, there might be instances where the sensor malfunctions or needs resetting. Among the various suggested methods available, some individuals may consider disconnecting the battery as a solution.

We will explore whether disconnecting the battery can reset the crankshaft sensor. By understanding this process, you can make an informed decision and take appropriate measures to rectify any issues related to the crankshaft sensor, ensuring optimal engine performance. So let’s dive in and uncover the truth behind this common belief.

What Is A Crankshaft Sensor?

Function Of The Crankshaft Sensor

The main function of the crankshaft sensor is to monitor the rotational speed and position of the crankshaft. It sends this data to the engine control unit, which utilizes the information to determine the precise timing for ignition and fuel injection. Additionally, this sensor aids in identifying any misfires and helps to regulate the engine’s overall performance.

Importance Of The Crankshaft Sensor

The crankshaft sensor holds significant importance as it directly influences the engine’s functionality and efficiency. Without accurate data from this sensor, the engine control unit would struggle to coordinate ignition and fuel injection properly, leading to potential misfires, decreased performance, and reduced fuel economy. Therefore, the proper functioning of the crankshaft sensor is crucial for the overall health and performance of the engine.

Effects Of Disconnecting The Battery

Immediate Impact On The Crankshaft Sensor

When you disconnect the car battery, it can cause a temporary disruption to the power supply of various electrical components, including the crankshaft sensor. This disruption can result in the sensor losing its stored data, which may include important information about the crankshaft’s position and rotation.

The loss of this data can have immediate consequences on the engine’s performance. Without accurate information from the crankshaft sensor, the engine control unit (ECU) may struggle to correctly adjust the fuel injection timing and ignition timing. As a result, you may experience issues such as rough idling, stalling, difficulty starting the engine, or a decrease in overall power and efficiency.

Potential Reset Of The Crankshaft Sensor

While disconnecting the battery can initially cause the crankshaft sensor to lose its data, it may also trigger a reset process. In some cases, disconnecting the battery can effectively clear any stored error codes or glitches in the car’s electrical system. This reset can extend to the crankshaft sensor, allowing it to recalibrate and reestablish proper communication with the ECU.

However, it is important to note that not all vehicles will reset the crankshaft sensor through battery disconnection alone. Modern cars rely on complex systems and may require additional steps, such as an ECU reset or sensor relearning process, to fully restore proper functionality to the crankshaft sensor.

Therefore, if you suspect an issue with your crankshaft sensor and are considering disconnecting the battery as a potential solution, it is advisable to consult your vehicle’s manual or seek professional assistance. This ensures that you follow the correct procedures and avoid further complications.

Factors Affecting Crankshaft Sensor

Age and Condition of the Vehicle

In older vehicles, the crankshaft sensor may become less accurate due to wear and tear over time. The sensor could also be affected by the overall condition of the vehicle, including any leaks or damage that may have occurred. It is important to regularly inspect and maintain the vehicle to ensure the crankshaft sensor is in good working order.

Type of Crankshaft Sensor

There are different types of crankshaft sensors, including Hall-effect sensors and electromagnetic sensors. The type of sensor used in a vehicle can affect its performance and reliability. Hall-effect sensors are more commonly used in modern vehicles as they provide more accurate readings. However, electromagnetic sensors can still be found in older vehicles. Understanding the type of sensor in your vehicle can help you troubleshoot any issues.

Understanding these factors can help determine whether disconnecting the battery will reset the crankshaft sensor. While it may temporarily reset the sensor, it is not a foolproof solution. If the sensor is old or damaged, resetting it may not solve the underlying issue. It is always recommended to diagnose the problem thoroughly and address any underlying issues to ensure the proper functioning of the crankshaft sensor.

Overall, the age and condition of the vehicle, as well as the type of crankshaft sensor used, are important factors to consider when troubleshooting any issues with the crankshaft sensor. Regular maintenance and proper diagnosis are essential for maintaining the performance and reliability of this crucial component.

Mechanical Vs. Electric Crankshaft Sensors

Disconnecting the battery will not reset the crankshaft sensor in an electric crankshaft sensor system. However, in a mechanical crankshaft sensor system, disconnecting the battery can reset the sensor. It’s important to consult a professional mechanic for the best course of action.

Differences In Operation

Before exploring the potential effect of disconnecting the battery on crankshaft sensors, it’s important to understand the fundamental differences between mechanical and electric crankshaft sensors.

Mechanical Crankshaft Sensors: These sensors, commonly found in older vehicles, rely on a series of physical mechanisms to monitor the crankshaft’s rotation. They typically utilize a magnet and a coil, with the magnet attached to the crankshaft and the coil positioned nearby. As the crankshaft rotates, the magnet passes the coil, generating voltage pulses that are then used by the vehicle’s engine control unit (ECU) to determine the crankshaft’s position and rotational speed.

Electric Crankshaft Sensors: In contrast, electric crankshaft sensors, also known as magnetic crankshaft sensors, utilize a Hall-effect sensor or a magnetoresistive device to detect the position and speed of the crankshaft. This type of sensor is more commonly used in modern vehicles with electronic fuel injection systems. The Hall-effect sensor is placed near a toothed wheel on the crankshaft, which contains a series of notches or teeth. As the notches pass the sensor, changes in the magnetic field result in voltage changes that are converted into digital signals for the ECU to interpret.

Effect Of Battery Disconnection On Each Type

Now, let’s explore the potential impact of disconnecting the battery on these two types of crankshaft sensors:

Mechanical Crankshaft Sensors: Disconnecting the battery in vehicles equipped with a mechanical crankshaft sensor is unlikely to reset or affect the sensor directly. Since this type of sensor relies on physical mechanisms rather than electrical circuits, cutting power to the sensor won’t alter its operation or calibration. If you suspect a faulty mechanical crankshaft sensor, it’s best to inspect the physical components, such as the magnet and coil, for any signs of damage or wear.

Electric Crankshaft Sensors: In the case of electric crankshaft sensors, disconnecting the vehicle’s battery may potentially reset the sensor. This is because modern vehicles often have complex electronic systems that require a stable power supply to function properly.

When the battery is disconnected, the ECU and other control modules may reset to their default settings, including the calibration for the crankshaft sensor. However, it’s important to note that simply disconnecting and reconnecting the battery may not resolve any underlying issues with the sensor itself.

If you suspect a problem with the electric crankshaft sensor, it’s advisable to perform a thorough diagnostic check using specialized equipment or consult a qualified mechanic.

Steps To Ensure Crankshaft Sensor Functionality

Best Practices After Battery Disconnection

After disconnecting the battery, it is essential to follow these best practices to ensure the proper functionality of the crankshaft sensor:

- Wait for at least 10 minutes after disconnecting the battery: This allows the vehicle’s electronics to fully reset and eliminates any residual electrical charges.

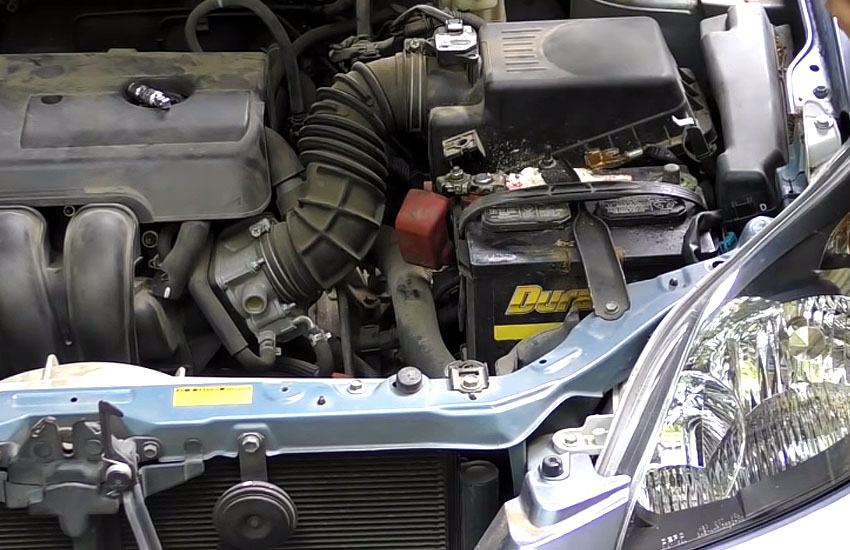

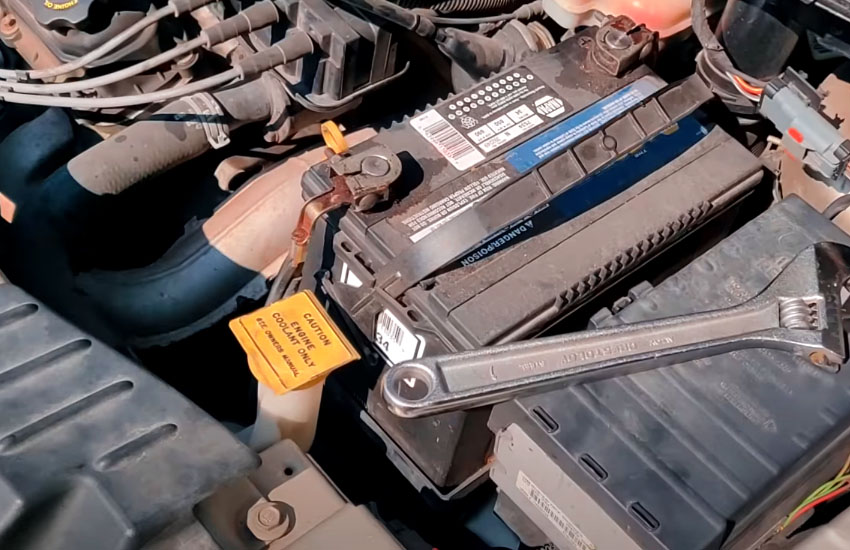

- Inspect the battery terminals: Check for any corrosion or loose connections. If necessary, clean the terminals and tighten any loose connections.

- Reconnect the battery: Make sure the battery is reconnected securely. Tighten the terminals but avoid over-tightening, as this may damage the battery.

- Turn on the ignition: After reconnecting the battery, turn on the ignition and wait for the vehicle’s onboard computer systems to initialize.

- Start the engine: Once the computer systems have initialized, start the engine and observe its performance. Pay attention to any abnormal sounds or warning lights.

- Test drive the vehicle: Take the vehicle for a short test drive to ensure that the crankshaft sensor is functioning properly. Monitor the engine’s performance and listen for any unusual noises.

Seeking Professional Assistance

If you encounter any issues or suspect that the crankshaft sensor is not functioning correctly after disconnecting the battery, it is recommended to seek professional assistance. A qualified mechanic or automotive technician possesses the expertise and necessary diagnostic tools to accurately diagnose and resolve any problems related to the crankshaft sensor.

Professional assistance offers several advantages, including:

- Diagnosis accuracy: A professional will be able to accurately diagnose the exact cause of any issues and determine whether the battery disconnection has affected the crankshaft sensor.

- Expert repairs: Professionals have the necessary knowledge and experience to perform any required repairs or replacements correctly.

- Time and cost savings: By seeking professional assistance, you can avoid potentially costly and time-consuming trial-and-error attempts to fix the problem yourself.

- Warranty protection: If your vehicle is still under warranty, seeking professional assistance ensures that any necessary repairs or replacements are carried out within warranty guidelines.

Final Words

Disconnecting the battery can potentially reset the crankshaft sensor in some cases. However, it’s important to remember that this approach may not work for all vehicles and situations. If you’re experiencing issues with your crankshaft sensor, it’s best to consult a professional mechanic who can diagnose the problem accurately and provide the appropriate solution.

Keeping your vehicle’s sensors and electrical components in good condition is crucial for optimal performance and avoiding potential breakdowns.